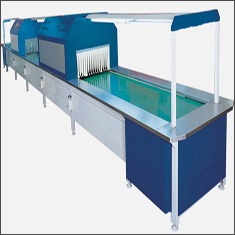

Shoes making assembly line Making shoes Product Round iron Line for sole attaching track

This production line uses stainless steel tube as conveyor belt, high temperature resistance, corrosion resistance, stepless variable speed motor as power, can adjust the speed at will. The inner lining of the fully enclosed environment-friendly drying channel is made of stainless steel plate, which is resistant to corrosion and high temperature, and adopts the principle of hot air circulation, with fast temperature rise, low sending off cost and good thermal insulation performance. The special closed exhaust device can discharge the harmful waste gas out of the room, purify the working environment and meet the requirements of environmental protection. Processing glue drying: the first glue drying, the second glue drying and activation, and can be quickly transported to the bottom of the joint.

The conveyor and drying oven at glue replenishment section can be mounted for the system for replenishment after sole pressing.

MODEL | Dimensions(LWH) | Packing size(LWH) | Weight | Production | Power | Voltage |

DF-798 | 12000*1250*780mm |

| 660KG | 1200pairs/8h | 1.5KW | 220V |

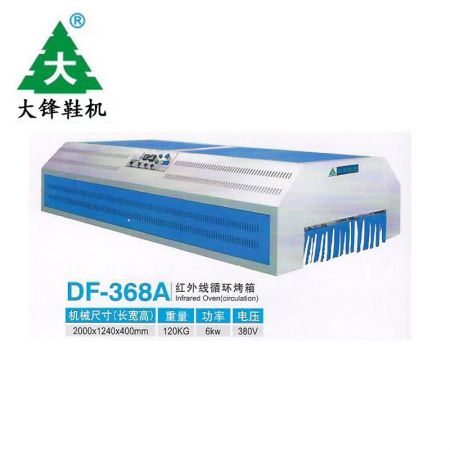

Shoes making assembly line Making shoes Product Round iron Line for sole attaching track

This production line uses stainless steel tube as conveyor belt, high temperature resistance, corrosion resistance, stepless variable speed motor as power, can adjust the speed at will. The inner lining of the fully enclosed environment-friendly drying channel is made of stainless steel plate, which is resistant to corrosion and high temperature, and adopts the principle of hot air circulation, with fast temperature rise, low sending off cost and good thermal insulation performance. The special closed exhaust device can discharge the harmful waste gas out of the room, purify the working environment and meet the requirements of environmental protection. Processing glue drying: the first glue drying, the second glue drying and activation, and can be quickly transported to the bottom of the joint.

The conveyor and drying oven at glue replenishment section can be mounted for the system for replenishment after sole pressing.

MODEL | Dimensions(LWH) | Packing size(LWH) | Weight | Production | Power | Voltage |

DF-798 | 12000*1250*780mm |

| 660KG | 1200pairs/8h | 1.5KW | 220V |