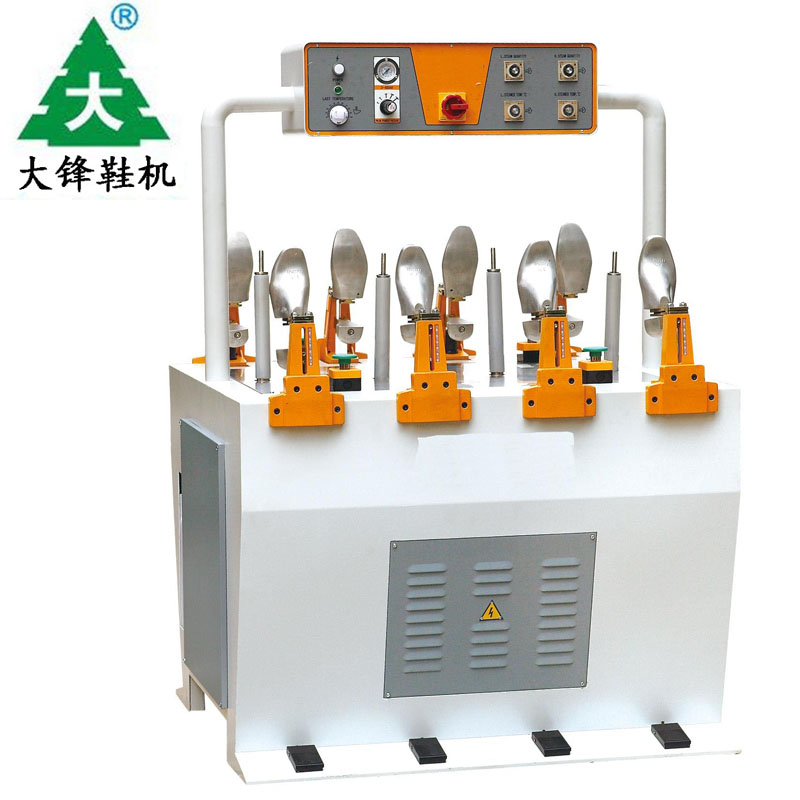

two cold and two hot counter moulding machine for stitch-down shoes picture

two cold and two hot counter moulding machine for stitch-down shoes feature

1. The machine for thermoplastic and thermo board counter moulding for stitch down process shoes. It is convenient to operate and save space.

2. Cushion with rapid connection for a quick change of work. Cushion press directly on customer last.

3. Leaning mould towards to the operator, and Moveable mould column.

4. Moveable pincers give a perfect shaping for boot upper.

5. Micro-electronic processing system.

two cold and two hot counter moulding machine for stitch-down shoes specifications

Dimension | Weight | Voltage | Power | Air Pressure | Capacity |

900x1450x2000mm | 640kg | 220V/50HZ | 2.7kw | 0.6MPa | 1300Pairs/8H |

two cold and two hot counter moulding machine for stitch-down shoes picture

two cold and two hot counter moulding machine for stitch-down shoes feature

1. The machine for thermoplastic and thermo board counter moulding for stitch down process shoes. It is convenient to operate and save space.

2. Cushion with rapid connection for a quick change of work. Cushion press directly on customer last.

3. Leaning mould towards to the operator, and Moveable mould column.

4. Moveable pincers give a perfect shaping for boot upper.

5. Micro-electronic processing system.

two cold and two hot counter moulding machine for stitch-down shoes specifications

Dimension | Weight | Voltage | Power | Air Pressure | Capacity |

900x1450x2000mm | 640kg | 220V/50HZ | 2.7kw | 0.6MPa | 1300Pairs/8H |